Lubrication Culture & Management - Part 2

Lubrication Culture & Management

Lubrication Culture & Management

Many organizations jumped into implementing and using the latest maintenance technologies at enormous expense, all with a promised and expected immediate return on their investment. In many cases, those changes have not led to significant improvements and the technologies have not produced the benefits, despite the quality of the implemented technologies. We look into the entire business effectiveness by improving risk-safety, environmental integrity, energy efficiency, product quality, and customer service to mention a few.

The basis of an effective lubrication Management is to provide; the right product, in the right location, in the right amount, at the right time, in the right condition and by the right person - there are many other factors required. To successfully implement these lubricant related activities within a plant, it requires that all of the lubricant related activities fit into and become a part of the work process. It cannot stand on its own as a separate or extra task, but must be fully integrated and be part of the work culture.

The four main categories that are essential:

1. Management and Work Culture

A successful maintenance program requires a management team and an organizational structure that, through good communication and informed knowledge, can provide effective maintenance decisions. Management must set forth a business plan that includes the organization's goals, objectives and expectations. By providing a clear understanding of all maintenance roles and responsibilities, the individuals involved in the maintenance activities can be held accountable.

2. Maintenance Work Processes

The maintenance work processes must start by identifying the correct maintenance activities while providing a path to include work initiation, work execution and work completion. This workflow process must also include the integration of procurement and scheduling of parts that will be used in the maintenance activities.

3. People Skills and Human Resources

A well-trained work force is a prerequisite for any maintenance approach to be successful. The work culture, management and staff 'buy-in,' training requirements, and people skills are all critical for success.

4. Technologies

This category focuses on the tools required to support the staff. There have been significant advancements in the technologies that can help an organization meet its goal of keeping the plant commercially available. These can range from maintenance and diagnostic systems to information integration systems.

Lubrication Management

The Lubrication Management needs to begin in ensuring all equipment-specific information regarding the critical equipment; maintenance, procedures, and technologies that are presently in place are accurate and up-to-date. By evaluating these issues, timely and beneficial recommendations can be made which focus on elements essential for immediate benefits as well as targeting medium and long-term reliability goals.

An effective lubrication management should produce significant benefits in plant reliability and equipment availability. Conducting an internal or external assessment of your existing lubrication program and comparing it to industry "Best Practices" will provide a needed gap analysis for identifying both strengths and weaknesses. Once identified, a focus on improvements can be made that yield optimal performance.

The areas for review in a Lubrication Program Management would be:

- Standards, Consolidation & Procurement

- Storage, Handling and Disposal

- Lubrication and Re-Lubrication Practices

- Contamination Control

- Sampling Methods and Collection

- Lubricant Analysis Program

- Safety Practices

- Procedures, Guidelines and Training

- Program Management

- Program Goals or Metrics

Lubricant Selection

The first, and most important step, is selecting and using the correct equipment-specific lubricants. By simply selecting the proper lubricant, the life of both the equipment and lubricant will be extended, which should be a cornerstone goal of the Lubrication Management System. These elements or components move by sliding, rolling, approaching and receding or a combination of these actions and require a lubricant designed to avoid contact between the surfaces.

The first, and most important step, is selecting and using the correct equipment-specific lubricants. By simply selecting the proper lubricant, the life of both the equipment and lubricant will be extended, which should be a cornerstone goal of the Lubrication Management System. These elements or components move by sliding, rolling, approaching and receding or a combination of these actions and require a lubricant designed to avoid contact between the surfaces.

The specific lubricant (viscosity, base stock and additive package) used will ultimately be based on the equipment design, the material, the surface finish, the geometry of the components and the operating conditions (i.e. load, speed, and temperature). To generalize based on the equipment design, the lubricant viscosity and additives must create an acceptable film thickness to maintain a separation of the moving elements (See Figure 1). If contact of the surfaces occurs, then high frictional forces will lead to high temperatures, lubricant degradation and unacceptable wear of the components.

Lubrication is an essential design principle of the equipment and is accentuated by modern machines that operate at higher speeds, under heavier loads and with closer mechanical tolerances.

Building the Foundation

Building the Foundation

An effectively installed Lubrication Management System benefits most departments within a facility, including engineering, operations and maintenance. It manages the process of lubricant selection, assessment, procurement, storage, handling, monitoring, and disposal, to ensure the safe, reliable and economic operation of lubricated equipment.

Identifying the equipment-specific lubricant requirements creates the foundation of this system. This includes OEM design features, operational parameters, maintenance activities or implemented modifications. This data is referred to as the "technical basis" for lubricant selection. Once collected, this data should be maintained within a controlled database (a Lube List) that provides a direct link between the equipment identification and justification for lubricant selection.

Manufacturer's Recommendations

Manufacturer's Recommendations

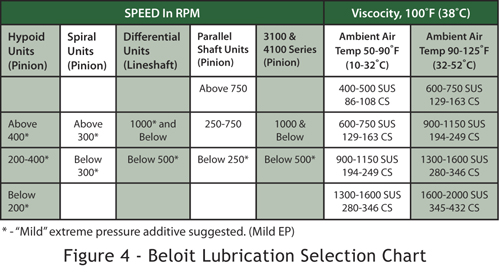

In their operating or maintenance manuals, manufacturers may recommend lubricants by brand name or by specifying the lubricant characteristics required for a particular operating condition. Figure 4 is an example of a manufacturer that provides good detail of the equipment conditions, but little detail on the lubricant requirement itself. Using the information in Figure 4, we can determine that a parallel shaft unit at an operating speed of less than 250 RPM and operating within an ambient temperature range of 90° to 125°F (32° to 52°C) will require a lubricant that is an ISO VG 320 with a mild EP additive. This information and lubricant selection is based on this particular unit with these specific operating conditions.

Although the amount of information varies from each oil producer, it generally includes the intended use, the additives (AW, EP, R&O), oil type (i.e., paraffinic, naphthenic, synthetic, compounded), and some of the technical specifications or test results. Understanding and comparing lubricant qualities and the provided test results (i.e. Pour Point, "C - ASTM D 97 or 4 Ball EP Test - ASTM D 2783) can become very difficult without a prior knowledge of the test methods and the expected results.

Figure 5 is a very basic lubricant comparison chart that can have specific test method results added to assist in the selection or substitution process

Armed with the equipment specific OEM advised lubricant, it does not mean that we have necessarily chosen the best lubricant for the application. This selection is just the starting point, as the final selection should include a process of past operating experience and the equipment criticality outlined within the facility's maintenance strategic objectives.

Operation and maintenance activities that have historically utilized a lubricant which provides acceptable equipment reliability within the desired operating costs could remain the lubricant of choice. However, to remain globally competitive, avenues for continued improvement should be explored. These improvements could be in the direction of:

- Advanced equipment protection

- Improvements in Worker Health and Safety

- Compliance with environmental regulations

- Lower yearly energy requirements

The next step requires an understanding that all effective maintenance and/or lubrication management systems require plant equipment to be categorized into criticality levels. This strategy determines a numerical ranking of the plant assets (systems and equipment) according to their commercial availability, safety, environmental, cost and efficiency requirements. Regardless of the method used, understanding and utilizing a ranking system should allow focus on selecting lubricants that provide:

- Cooler operation or lower operating temperatures (less heat from friction)

- Longer equipment and mechanical components life (due to lower friction and wear)

- Increased oil life (lower wear metals and reduced oil oxidation)

- Lower maintenance cost (fewer oil changes and disposal costs)

- Energy Savings (less energy lost to friction)

In many instances, these same lubricant requirements for critical equipment should be reviewed for the equipment deemed to be less critical and moved into the run-to-failure mode. An example would be a gearbox or reducer that, if filled with clean, dry high performance synthetic gear lubricant and then allowed, as per the maintenance strategy, to run-to-failure. This gearbox should provide an increased life expectancy coupled with a reduction in overall energy usage for a very small investment in the synthetic lubricant over a lower priced commodity gear lubricant.

In many instances, these same lubricant requirements for critical equipment should be reviewed for the equipment deemed to be less critical and moved into the run-to-failure mode. An example would be a gearbox or reducer that, if filled with clean, dry high performance synthetic gear lubricant and then allowed, as per the maintenance strategy, to run-to-failure. This gearbox should provide an increased life expectancy coupled with a reduction in overall energy usage for a very small investment in the synthetic lubricant over a lower priced commodity gear lubricant.

Finally we move into the facility's consolidation of the lubricants. This definitely has advantages, including reduced inventories and reduced storage requirements due to the overlap of "like" lubricants. In too many cases, the sole criterion for consolidation is cost. Often times, decisions to take advantage of price breaks given for bulk purchases result in overlooking the technical requirements, quality implications, or the effects of interchangeability of lubricants. These all have a significant adverse effect on equipment reliability. Consolidation should be accomplished through the services of a lubricant specialist or a facility employee who has knowledge of the equipment's operating characteristics, the lubricating requirements, and has an ability to understand the lubricant producer's technical data sheets.

Equipment reliability requires that the selected lubricant meets and maintains specific physical, chemical and cleanliness requirements. A detailed trail of a lubricant is required which begins with the OEM (lubricant supplier) and ends after disposal. Sampling and testing of the lubricants is required to validate the condition of the lubricant through all these phases.

Lubricant Supplier - Quality control programs implemented by the lubricant manufacturer should be questioned and recorded when evaluating the supplier. Sampling and testing new lubricants before dispensing ensures that the vendor has supplied the correct lubricant.

Lubricant Storage - Correct labeling (including MSDS) must be clearly installed to ensure proper use of the enclosed contents. Proper stock rotation and storage methods must be taken into consideration to prevent the degradation of the physical, chemical and cleanliness requirements of the lubricant throughout the storage and dispensing phase.

Handling and Dispensing - Handling and dispensing methods must ensure that the health and the cleanliness of the lubricant meet the specifications required by the equipment. All opportunities for contamination must be eliminated. Pre-filtering of all lubricants must be performed to meet the specific equipment requirements. Information for all Preventive Maintenance activities involving oil drains, top ups, sweetening, flushing or reclaiming, should be recorded and forwarded to the individual responsible for the oil analysis program group in a timely manner. Record keeping of any activity involving lubricant consumption, lubricant replacement and/or lubricant top-ups performed must be implemented and maintained. Visual management techniques should be utilized to ensure the correct lubricant is being used for each lubrication point.

Oil Sampling Location(s) - A sampling location should be determined to allow for trouble-free, repetitive and representative sampling of the health of the equipment and the health of the lubricant. The sampling method should allow the equipment to be tested under its typical operating condition and allow a safe sampling procedure for the technician.

Tests - As a general rule, oil analysis encompasses four categories of tests: (1) Fluid physical properties, (2) Fluid chemical properties, (3) Fluid contamination, and (4) Machine health. A general routine group of tests does not necessarily take into consideration the machine specifics. Equipment specific testing will supply the required data to effectively monitor and trend the health of the lubricant and the equipment, while exception tests verify a root cause of change.

Targets and Alarms - OEM operating specifications or a recognized governing body can be used in setting the minimum alarms. These alarms must be set taking into consideration all of the above collected information. These settings must provide early detection of contaminants, the deterioration of the lubricant and the current equipment health. These achievable targets should be set to supply an early warning of any anomalies, which will allow corrective actions to be scheduled and performed with little or no effect to production schedules.

Waste Oil - Oil deemed unfit for equipment usage must be disposed of in the correct storage container for that type of lubricant and properly marked and labeled. The lubricant must then be classified for the proper type of disposal and removed from the property without delay. Long storage times allow for the introduction of contaminants (e.g. water) and other fluids, and could in some cases result in re-classification.

Database Development - A database should be developed to organize equipment information, the collected data and the equipment specific targets and alarms. This database must allow for smooth operation of data entry as well as have excellent capabilities for performing the analytical work. The end user must have control of the targets and limits in order to reflect the true equipment specific conditions within the plant.

The Lube List

After collecting, calculating, and evaluating the technical basis for lubricant selection, we need a controlled repository for this information. Microsoft Access and Excel are both flexible enough to accommodate this task, allowing custom fields and entry screens that can be accessed by all required plant personnel. While this Lube List doesn't have to be part of a work management system, an individual that is competent in lubrication management should control it.

At this point, the lubricant specifications are now based on equipment-specific requirements. This information, the "Lube List", is stored in a controlled location. The final step is to create a document to define these lubricant specifications, the purchasing criteria, and the actual receipt of new lubricants to ensure the quality of the lubricant.